-40%

TPI 709R Combustion Efficiency Analyzer

$ 316.78

- Description

- Size Guide

Description

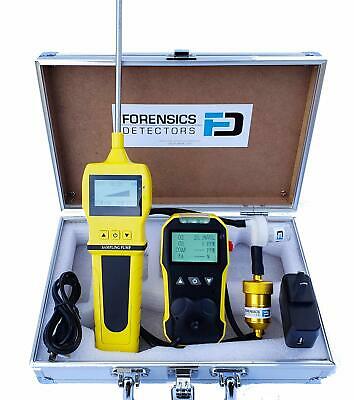

AUTHORIZED DISTRIBUTORCombustion Efficiency Analyzer w/ Differential Manometer.

The carbon monoxide sensor used in TPI combustion efficiency analyzers feature an on-board filter capable of filtering NO (nitric oxide), NO2 (nitrogen dioxide) and NOX (combination of NO and NO2) to prevent cross sensitivity errors.

Use TPI analyzers to test flue gases in gas and oil fired equipment including high efficiency furnaces and condensing boilers. Measure CO, O2, and stack temperature.

Determine combustion efficiency, CO2, and CO air free. Built-in differential manometer, combustible gas detection, PC communication, data logging, and can measure NO / NOX.

All the features of the 709 PLUS Rechargeable Batteries

Measure CO, and temperature

Calculate CO2, efficiency, excess air, and CO air free

Includes:

TPI 709R Instrument;

Rubber Boot (A765);

Battery Charger (A766);

Soft Carrying Case (A768);

Flue Sampling Probe (A770);

In-Line Filter assembly installed on Flue probe (A794);

Temperature Probe (GK11M);

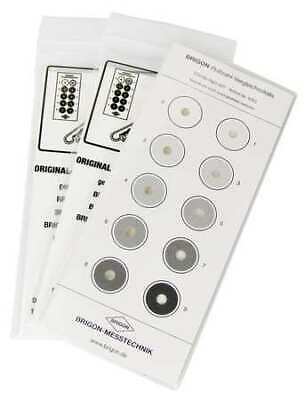

Mini Pump Protection Filter Assembly and spare filters (A763);

Exhaust Spigot (removable) (A764);

Instruction ManuaL;

Combustion Efficiency Analyzer and Differential Manometer.

The carbon monoxide sensor used in TPI combustion efficiency analyzers feature an on-board filter capable of filtering NO (nitric oxide), NO2 (nitrogen dioxide) and NOX (combination of NO and NO2) to prevent cross sensitivity errors. Use TPI analyzers to test flue gases in gas and oil fired equipment including high efficiency furnaces and condensing boilers. Measure CO, O2, and stack temperature. Determine combustion efficiency, CO2, and CO air free. Built-in differential manometer, combustible gas detection, PC communication, data logging, and can measure NO / NOX.

Features

Built-in differential manometer with 0.001" H2O resolution;

Calculates combustion efficiency;

Pump driven for fast response;

Will not shut off if 15 ppm CO is present for increased safety;

Ten selectable fuels: Natural Gas, LPG, Light Oil, Heavy Oil, Bituminous Coal, Anthracite Coal, Coke, Butane, Wood, Bagasse;

Optional A740 IR printer available for hard copies of test results;

Built-in differential thermometer;

Store function to save up to 50 readings;

Large easy to read backlit display;

Rechargeable Ni-MH Battery with > 6 Hours battery life;

Applications:

Tuning of residential and furnaces and domestic boilers;

Ambient and stack testing for CO;

CO safety measurements in and around combustion sources;

Temperature checking, including superheat and hydronic differential temperatures;

Dual input differential manometer;

Model 709R Specifications

Carbon Monoxide (CO)

Measurement

Range 0 to 10,000 ppm

Resolution 1 ppm

Accuracy +/-5ppm or 5% of reading whichever is greater

Oxygen (02) Measurement

Range 0 to 25%

Resolution 0.1%

Accuracy ±0.3%

Carbon Dioxide (CO2)

Range 0 to 25%

Resolution 0.1%

Calculated Value

Nitric Oxide Measurement

N/A

NOX Measurement

N/A

Temperature Measurement

Range -40 to 1472°F, or -40 to 800°C

Resolution 1°F or °C

Accuracy (K-type) ±0.3%, ±2°F or ±1°C

Draft/Pressure

Measurement

Selectable Ranges mBar,kPa, and inH2O

Ranges -150 mBar to +150 mBar -15 kPa to +15 kPa -60

inH2O to +60 in H20

Resolution 0.001 inH2O

Accuracy ±0/5% fsd

Gross/Net Efficiency

Range 0 to 100%

Resolution 0.1%

Calculated Value

CO/CO2 Ratio

Range 0 to 0.999

Resolution 0.001

Calculated Value

Operating Temperature

14°F to 122°F (-10°C to 50°C)

Battery Type

Rechargeable Batteries

Selectable Fuels

Natural Gas, LPG, Light Oil, Heavy Oil, Bituminous Coal,

Anthracite Coal, Coke, Butane, Wood, Bagasse

Display Type

Backlit 3 line LCD

Data Storage

50 Locations

Data Logging

N/A

Print Capability

Yes, via optional IR printer (A740)

PC Communication

N/A

Date and Time Function

24 Hour Real Time Clock

Dimensions

200mm x 90mm x 60mm

Weight

500g

Conformity

BS7927 (and the draft BS7967)

Frequently Asked Questions

When should I use the optional A773 oil filter?

If your analyzer is used in an oil fuel application the A773 filter should be used. This filter does not have to be removed for other fuel types.

Should I set my analyzer to net or gross efficiency?

Gross efficiency is the correct choice for applications in the United States.

Can I use any of the TPI analyzers to test for the presence of combustible gas in the flue?

Yes, the 712 has the ability to test for combustible gases in the flue.

Can I log and send test data to a computer?

Yes, the 712 and 714 have the ability to communicate to a computer by using the optional A767 infrared adapter.

Can I test for CO in ambient air?

Yes, the 708, 709, 712, and 714 can all test for carbon monoxide in ambient air.

Do any of the TPI analyzers have a built in manometer?

Yes, the 709, 712, and 714 have built in differential manometers.

Tech Tips

Several factors affect combustion efficiency.

Dirty or clogged air filters reduce the amount of air available for combustion therefore reducing efficiency. Obstructions in the flue block exhaust gases and alter the air mixture in the combustion chamber which reduces efficiency. Air leaks in the combustion chamber also alter the mixture causing decreased efficiency.

The primary way to affect change in combustion efficiency when working with modern gas fired equipment is through gas manifold pressure adjustment.

Confirm manifold pressures are within manufacturers specifications prior to performing a combustion test. Once manifold pressures are within limits a combustion test can be performed to provide information regarding any adjustments that may be needed.

10,000ppm is equal to 1%.

The formula to convert percent to ppm is: ppm = %gas X 10,000. The formula to convert ppm to percent is: % = ppm / 10,000.

The 709, 712, and 714 incorporate a differential manometer.

Pressure applied to the (-) port is subtracted from the pressure applied to the (+) port. Examples of pressures being measured:

(+) port = 10"H2O, (-) port = Not Connected, Displayed reading =10"H2O

(+) port = 10"H2O, (-) port = 5"H2O, Displayed reading = 5"H2O

(+) port = Not Connected, (-) port = 10"H2O, Displayed reading = -10"H2O

Sensor Calibration

The sensors in your analyzer will need to be replaced periodically and calibration is recommended once every year. Electrochemical sensors by nature are always active. Therefore the time the analyzer is off and not being used must be taken into account when determining sensor life. The sensors in your analyzer are warranted for two years. This warranty does not cover sensors damaged through misuse of the analyzer.